One of the questions we often get from our customers is how they can improve the performance and shorten the cycle times when using an ion mill.

Enter the Leica TXP Target Preparation Device

We find that the Leica TXP is a perfect complement to our ion mill.

The Leica TXP allows us to prepare samples by trimming, milling, and grinding them to target the specific location we will want to ion mill. By trimming away unnecessary material, our samples spend less time in the ion mill.

Spending less time milling not only saves processing time but reduces ion gun time, therefore reducing wear and keeping the milling chamber cleaner. In addition, targeting our ion milling more accurately prevents issues that may be caused by the ion beams being deflected by covers/lids or other materials that are of no interest.

Wedge Your Sample for Faster Ion Milling

One quick and easy method to increase ion milling productivity is to “wedge” your sample by cutting and grinding.

Wedging your sample removes much of the unwanted material and allows quick access to the target area for ion milling. As a result, ion milling time and cost are reduced.

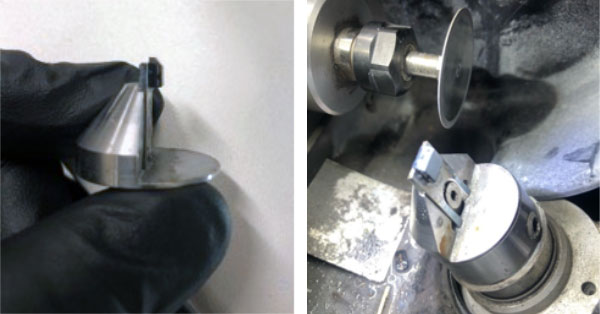

In figures 1 and 2 below, we show a semiconductor packaged device that has been wedge cut on the TXP before it is put in the ion mill.

You can gain an additional advantage by using a standard SEM holder on the TXP.

You can see, in both images, that we can process the sample while it is on a standard SEM holder. The sample can be easily placed into the ion mill and then into the SEM without additional mounting. This results in even more cost and time savings.

If you have questions or need assistance with your sample preparation process, please use the form on this page to contact us. Or, give us a call at (408) 436-6336.