Another challenge we face in the lab is preparing very soft, delicate, samples like polymer films, urethane, and silicone samples without damaging internal layers. This damage could impact our ability to look at the material structure in our SEM.

We have found the most success in polishing soft materials using cryo ion milling.

In a cryo ion mill process we cool the samples to -160° Celsius because the energy of the ions will melt delicate materials.

Room temperature ion milling is great for polishing without creating scratches and smears, but ion energy can still melt the material.

Keeping the cross-section cold prevents damage from heat generation and maintains the integrity of layers and internal structural information.

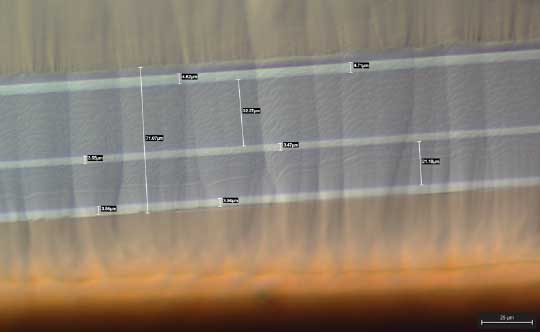

Below is an image of a very thin polymer comprised of multiple layers.

This sample was a cryo ion milled at a low voltage for a couple of hours. We added some dimensional measurements to make it easier to see just how small the individual layers are.

The image was taken with an optical microscope at 500X using DIC (Differential Interference Contrast). It highlights surface height changes so we can see the “fish scale” effect of ion milling instead of the traditional scratches formed by mechanical polishing.

The surface pattern will not be visible in an SEM or under standard brightfield illumination on an optical microscope. There is no deformation of the sample or of the individual polymer layers. The total width of the film is ~70uμ and layers are under 5uμ.

We have the right equipment in our analytical lab to help you safely process these types of samples. If you need assistance, please complete the form on this page or give us a call at (408) 436-6336.